We have delivered

1000+ Projectsin the USA

Our Projects

- Stadium

- Bridges

- Industrial

- Commercial

- Warehouses

- Other Structures

The 973.5 ft. long, $28.7 million “41st Street Bridge” received the AISC award for the best bridge under the Special Purpose Bridges category for 2020.

It features double-curved arch mono trusses to form large, graceful S-curves. The bridge contains three segments in its total span. The segments are called East & West Approaches at the ends and the Main span in the middle.

The main span has two spans with a length of 239 ft 5 inches and is supported at both ends & middle. It is suspended on both sides of the middle support by using the Arches and suspended Hangers.

The Arch is fabricated from a 48-inch diameter steel pipe with 1 inch thick and mounted over the Thrust block. The Main Rib 48 inches & Arch location are changed to follow the S-curve. The suspended hangers are connected from the Arch to the Main span Ribs.

The bridge’s central Rib is fabricated from a 30-inch diameter steel pipe, either 1 ¼ inch or 1 ¾ inch thick depending upon span and strength requirements. At the top of the pipe, shear studs are added, which enable composite action between the steel and the path’s 8-inch thick, 17 ft wide concrete deck.

The pedestrian bridge provides a safe and modern crossing between the east and west sides of the Arkansas River. It is located 45 ft (13.7 m) above the Arkansas River.

This bridge is 1,440 ft long and is supported by eleven 120 ft-long arch spans and an approach span. The semi-integral bridge was designed with extremely slender deck-stiffened arches built from a 3-1/4″ plate of weathering steel and is curved in plan.

It is the longest arch-type pedestrian bridge in the United States and the first multi-span, plate arch bridge built in the US.

With many site constraints and limited clearances, a meander (bend or curve or spine rib or roller coaster) form was essentially the only option for the grade-separated pathway. A dramatic steel spine-rib superstructure support achieved the objectives of both form and function. The longitudinal spine-rib support system accommodates the complex bridge’s need to curve both horizontally and vertically and provides the desired aesthetics.

The bridge’s central spine is fabricated from 30 inch diameter steel pipe, either 1 ¼ inch or 1 ¾ inch thick depending upon span and strength requirements. A T-shaped web and flange are welded on top of the pipe to provide added strength and a surface for shear studs, which enable composite action between the steel and the path’s 6 inch thick, 17 ft. 10 inch wide concrete deck. Rib elements, fabricated from steel plates, are connected to each side of the steel spine on 8 ft. centres, tapering in depth from approximately 2 ft. 2 inch at the central spine to less than 5 inch at the outer deck edge to create a sleek, graceful appearance. A longitudinal steel channel, running parallel to the steel pipe spine, is supported by steel columns created from 1 ¼ inch steel plate bent into a 30 inch by 22inch elliptical shape. The elliptical column extends 2 ft. below the bottom of the spine before separating into two half-elliptical column legs that splay apart to create a wider base for additional stability.

The Chicago Transit Authority (CTA) completely rebuilt the northern portion of the Red Line from Belmont station to Howard station and the Purple Line from Belmont station to Linden station. The Red and Purple Modernization (RPM) Program replaces the old, deteriorating infrastructure and stations along Chicago’s busiest rail line, paving the way for CTA to significantly increase train capacity and improve service for generations to come. Esskay executed the detailing of this prestigious project and delivered it ahead of schedule.

This $4.1 billion Legacy green field mega-project is the first new potash mine in Saskatchewan in over 40 years. The project was commissioned in 2016. The scope of this project included the main process buildings, which comprise nine major industrial structures. In addition to the steel structure, the project included rough-setting approximately 515 pieces of equipment and ninety large pipe/electrical modules.

Our scope consisting of four buildings weighing 8000 tons, was received in July 2014 and completed in 6 months, including 15% change orders. These equipment support structures typically included main steel, complex miscellaneous steel, Handrails, Stairs, Cage ladders, Safety gates, Removable gates, Checker plates, etc. All connections were fatigue-critical connections and therefore exceptional care had to be taken to meet this requirement.

This is an assembly shop for an auto major in Georgia, on a floor area of about 1.2 million Sq.ft. The workshop comprises various types of structural roof trusses, supporting columns, and miscellaneous steel. The total steel is around 8,000 tons.

This is a large Battery plant. It is the first large-scale, domestic electric vehicle battery manufacturing facility on a 70-acre property. The steel structure weighs over 20,000 tons. The building is covered with IMP panels supported by girt structures running around the perimeters. It’s a complex job with heavy structural braces and parapet support steels, with a bridge connecting the intermediate buildings. It is a state-of-the-art plant and a challenging project.

Fuchs North America is a manufacturing and storage unit for commercial seasonings, spices, and other ingredients by Fuchs North America Inc. in Hampstead. The project value is $16 million and it is about 170,000 square feet area. The manufacturing unit has a huge steel tower for supporting blending plant. The blending tower has rigid braces and Z- Grits. The storage area has a hip and valley roof and is supported by joist and joist girders connected to steel columns. The office area is supported by steel beams framing to CMU and precast wall secured by steel embed plates. The lobby and canopy is a curved structure and is made of rolled beams.

The project consists of a single, 100-foot-tall logistics building in Tracy, California with a footprint of 824,000 square feet. The 5-story building includes four levels of 133,000 square feet of robotics-occupied sorting floors above the ground floor, providing approximately 3.5 million square feet of industrial processing and storage space.

The facility includes parking for more than 1,800 cars and 230 trailers and provides access to 40 loading dock bays.

We have been awarded by Reyami steel to detail the process pipe racks for the oil field. We have modelled the pipe rack with miscellaneous such as platforms, stair handrail and ladders.

MOBOT is the oldest Botanical Garden in St. Louis, USA. It has a long history in Plant Science Research. In 2020, Esskay was entrusted with the complete Detailing of the New Visitor Center, the gateway for more than one million visitors annually. The design reflects the bold, transformative vision of MOBOT. The project had a lot of challenging architectural designs and has won many awards. Esskay is proud to be associated with this Iconic Project.

Mercy Hospital is one of the largest groups of multi-speciality hospitals serving low-income groups across 4 States in the US. Esskay took up the detailing of the complete project expansion at the St. Louis facility in the year 2021. This included about 1700 tons of Structural and Miscellaneous Steel. This included some challenging miscellaneous work with a long-span camber truss. The Project was completed on schedule, despite a lot of challenges.

Detailing for this project was awarded in 2020. It comprised of the renovation of an existing Theater and a new Music Building, in Virginia. The existing theatre was converted from a 750-seat capacity to a 500-seat capacity. The new music building is a 450-seat Concert Hall and a 125-seat Recital Hall. It was a challenging project with a lot of site coordination and architectural and miscellaneous detailing.

SSM Health Saint Louis University Hospital, is a $550 million academic medical centre in the City of St. Louis. It is a 316-bed, 802,000-square-foot replacement hospital and an outpatient care centre.

The total tonnage of the steel structure is 4,700 tons. The columns & beam in the tower buildings are defined as heavy sections with CVN requirement. Some of the base plates are 4” to 6”thick.

The complexity of the job lies in the wall systems with bump out slabs. The walls are different type with glass mullions, terracotta walls & stone walls around the podium level with steel hanging supports.

This design and build project consist of three separate buildings:

Patient tower building (Total nine floors with roof, penthouse & penthouse Roof.)

Commons Building (Two floors with Roof & a monumental stair)

Addition Clinical Care building (Three floors & a roof)

This is a Warehouse project. It comprised a little over 600 tons of Steel. Esskay did the Structural & Miscellaneous steel. Yet another project was completed on time.

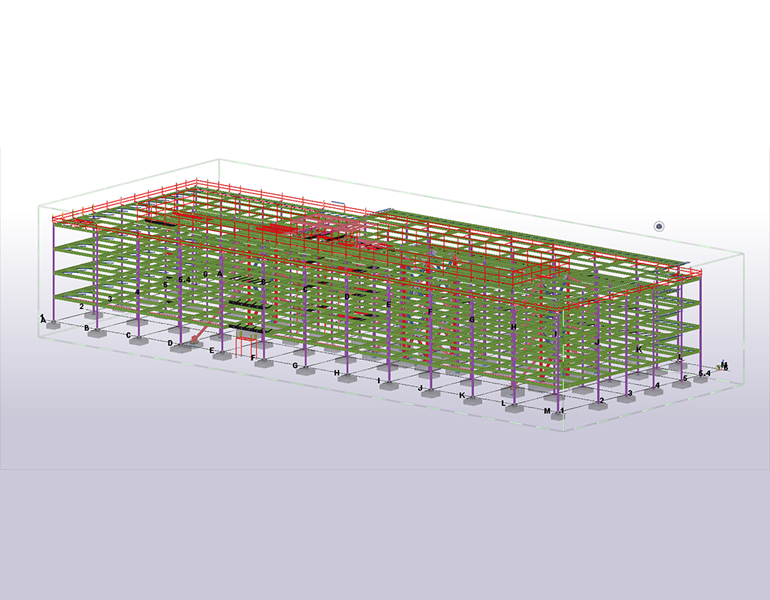

Project consists of a single, 100-foot-tall logistics building in Tracy, California with a footprint of 824,000 square feet. The 5-story building includes four levels of 133,000 square foot robotics-occupied sorting floors above the ground floor, providing approximately 3.5 million square feet of industrial processing and storage space.

The facility includes parking for more than 1,800 cars and 230 trailers and provides access to 40 loading dock bays.